CONTACT

Tel:

+52 77 9796 6345

+52 77 9796 6415

contacto@elastomerossigma.mx

Address

Libramiento Vial No. 35 Bodega “E”.

Col. Nacozari Mpio.

Tizayuca Hidalgo CP. 43804

ELASTOMEROS SIGMA S.A. de C.V. is a 100% Mexican company founded in 2007, which has the technology and experience of more than 30 years in the manufacture of rubber products, this allows us to stay at the forefront in the rubber industry in Mexico.

We are currently in the domestic market in the manufacture of extrusions, gaskets for potable water and sewage conduction, as well as molded parts in general.

ELASTÓMEROS SIGMA has a quality management system under the guidelines of the international standard “ISO 9001:2015” and that commits us to meet the requirements of our customers.

To work with professionalism to manufacture rubber products and thus meet the supply needs of the domestic market with quality, of the automotive, body shop, electrical and industry sectors in general and thus achieve customer satisfaction, generating jobs and welfare in the community.

Manufacture rubber products with the commitment to provide and increase the satisfaction of our customers, therefore, it: Maintains clear and transparent communication with customers and stakeholders Trains staff at all levels of the organization Implements and maintains continuous improvement Comply with the requirements of ISO 9001:2015. Complies with legal and regulatory requirements.

To have an economic and technological growth in the medium and long term in order to consolidate our position in the national market and enter the international market.

Commitment, quality, loyalty, honesty and leadership are the values promoted at ELASTÓMEROS SIGMA. To achieve the above, a quality management system is maintained under the guidelines of the international standard "ISO 9001:2015".

A cold feed extruder with variable speed and a die with the required shape, the rubber adopts this shape and passes through the hot air tunnel to be vulcanized, thus maintaining its shape and adopting its final properties.

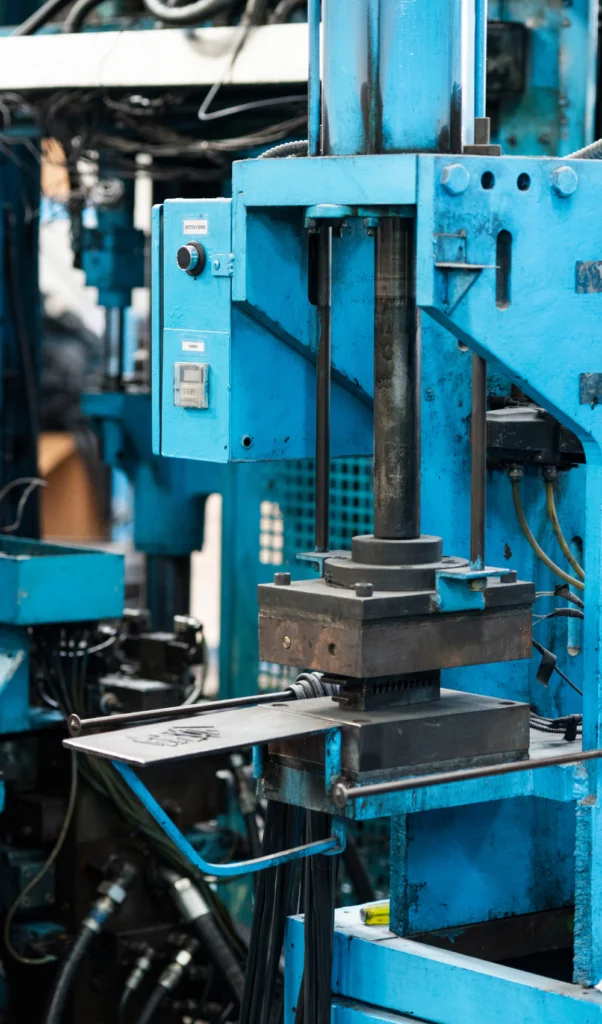

The rubber preform is placed in the cavities of the mold and this in turn is introduced into the platens of the press that through compression is given the shape of the final product, vulcanization is achieved by heat transfer generated by electrical resistances in the platens of the press.

Unlike the compression process, this is a high volume production process for small and medium size parts.

With injection molding, an exact amount of rubber is injected into a closed cavity formed by two halves of a steel mold which is preheated to the rubber curing or vulcanizing temperature.

We manufacture quality rubber products for which we have established a Quality Management System under the guidelines of ISO 9001:2015 with which our company is committed to meet the requirements of our customers.

Within our facilities we have a physical testing laboratory to ensure compliance with specifications according to the corresponding ASTM or NMX standards.

+52 77 9796 6345

+52 77 9796 6415

contacto@elastomerossigma.mx

Libramiento Vial No. 35 Bodega “E”.

Col. Nacozari Mpio.

Tizayuca Hidalgo CP. 43804

We are a leading manufacturer of high quality rubber products. We use continuous vulcanization, steam vulcanization, compression, injection and transfer processes to create products that are tailored to each customer’s needs.

+52 77 9796 6345

+52 77 9796 6415

contacto@elastomerossigma.mx

Libramiento Vial No. 35 Bodega "E".

Col. Nacozari Mpio.

Tizayuca Hidalgo CP. 43804

Copyright © ELASTOMEROS 2023. All rights reserved.